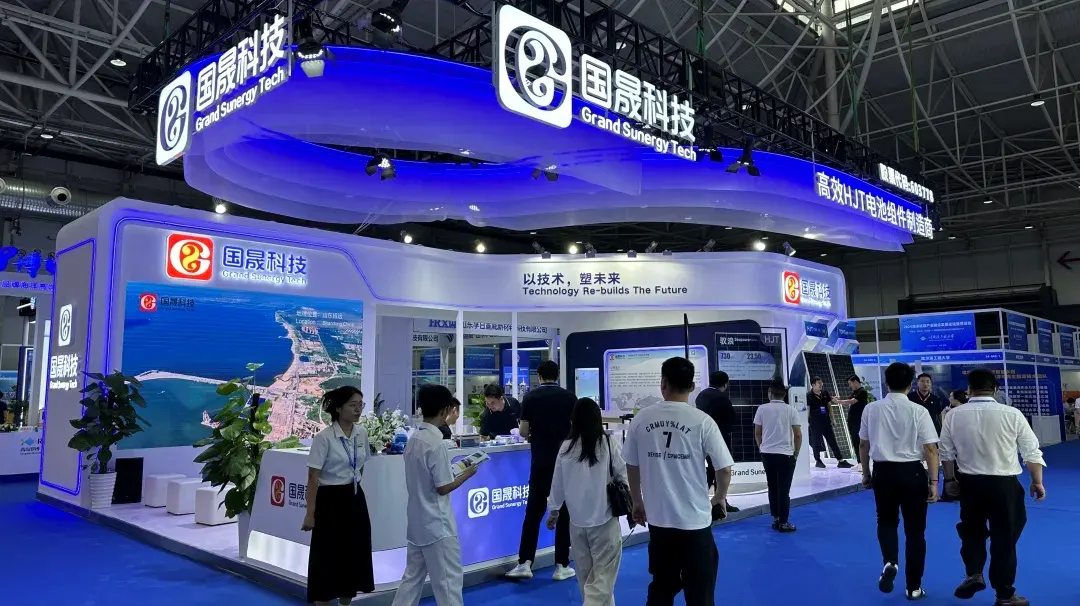

Human energy exploration is expanding into the oceans. On September 12th, at the Qingdao CMEIE, Grand Sunergy, as a co-organizer, made a stunning appearance, presenting its high-efficiency HJT heterojunction photovoltaic products and technical solutions.

High Durability, Scene-Based Product Features

Grand Sunergy exhibited three module products, with a scene-based display highlighting the high durability of its HJT products.

Among them, the Chasing Series 210-132 HJT Seapower Solar Module stood out as the most striking product. It boasts a maximum output power of 730W and a conversion efficiency of 23.50%. Specifically designed for offshore photovoltaics and saline-alkali flats, this module is based on its new generation bifacial microcrystalline HJT cell technology and 210mm large-size silicon wafers. It features a polyurethane polymer composite frame, which is sturdy and corrosion-resistant, capable of stable operation in high-salt fog and highly acidic environments. The module has also passed TÜV Nord’s wind tunnel test (maximum wind speed: 51m/s) and has strong mechanical load-bearing capacity, allowing it to withstand typhoons of up to grade 16. It is fully adaptable to the marine environment, including high salt fog, high humidity, intense UV exposure, and strong storms.

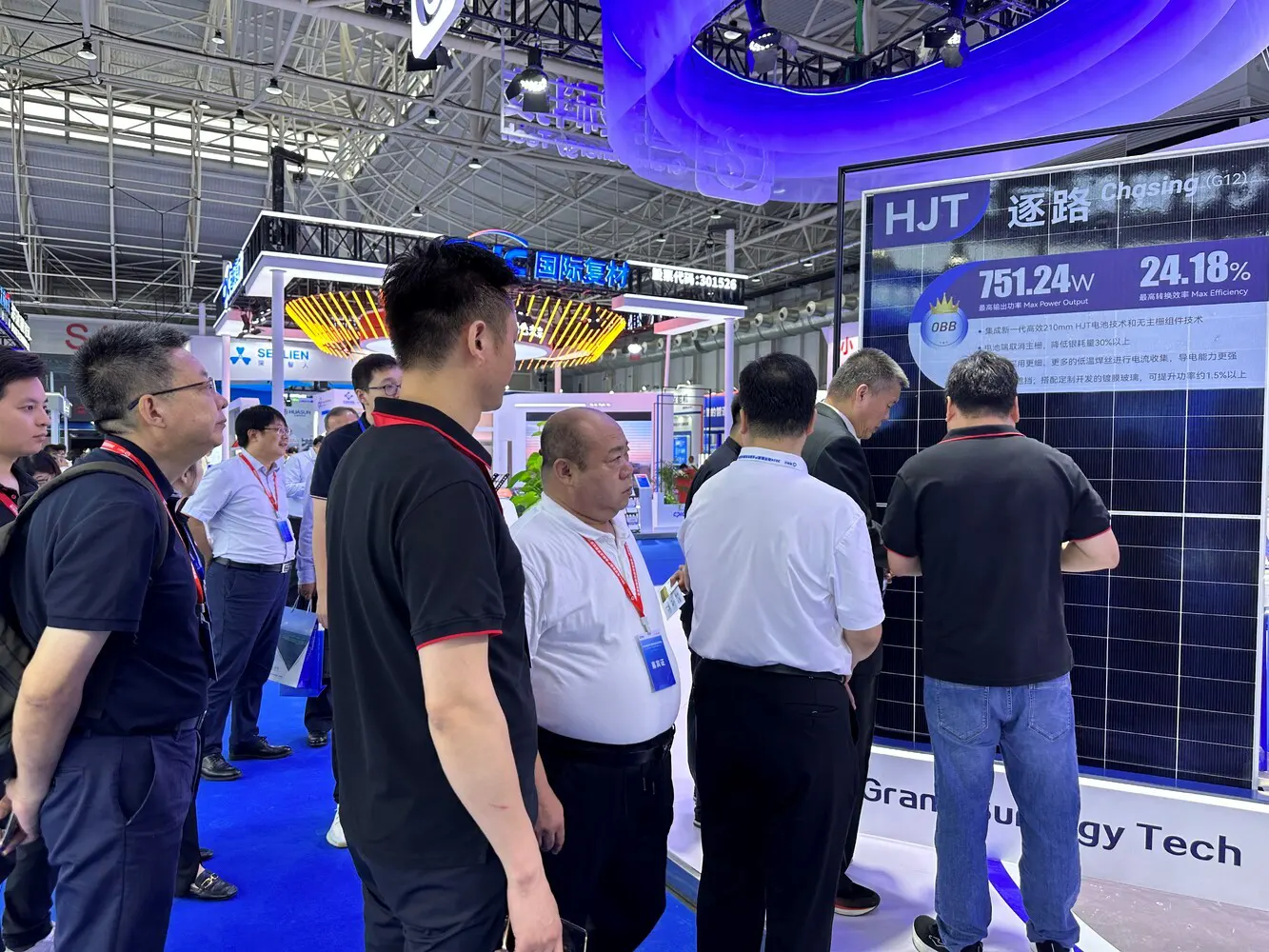

Another highlight of the exhibition was the Chasing Series 210-132 Ultra-High-Power HJT Module, with a maximum power output of 751.24W and an efficiency of 24.18%, as certified by a global third-party authority. This product utilizes 210mm large-size high-efficiency HJT cells and 0BB technology. Through a process that reduces impurities and defects within the cells, light absorption and conversion are significantly improved. The module features custom-developed dual-layer coated glass, light-transmitting films, and spacer films, making it a “hexagonal warrior” in offshore photovoltaic scenarios.

In the rooftop scenario, Grand Sunergy introduced the Eutropic Series 182-144 HJT-0BB Module. Utilizing 0BB busbar-free interconnection technology, the product minimizes silver paste shading on the front, increasing the light-receiving area by 30% compared to 20BB modules, thereby improving conversion efficiency. This module has a maximum output power of 610W and a conversion efficiency of 23.61%, outperforming mainstream products in the same category with higher output power and lower micro-crack loss, delivering about 1.7% more power.

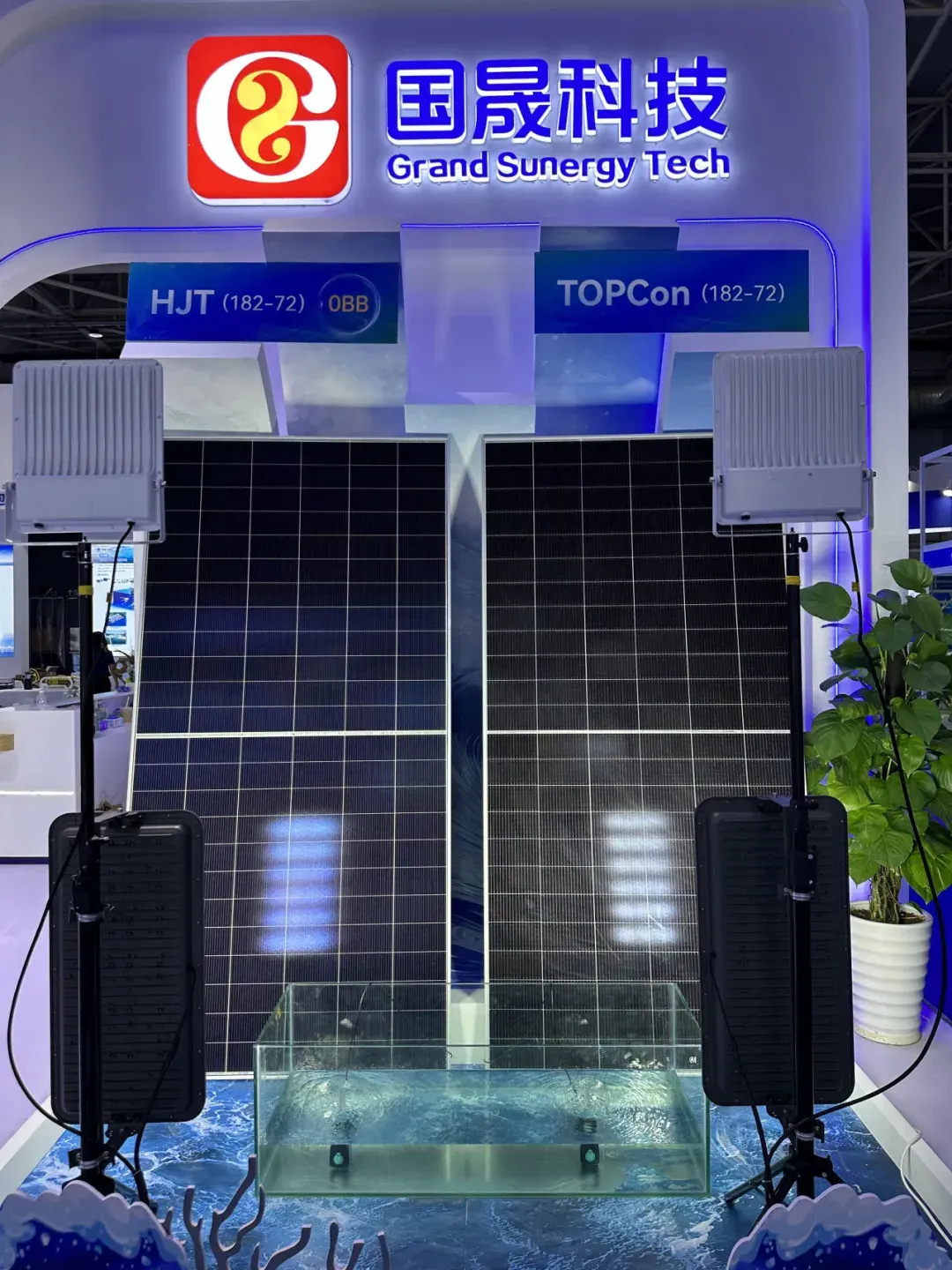

Notably, an on-site experiment was conducted comparing the HJT-0BB module to a TOPCon module. Under consistent external conditions, when the light intensity was gradually increased, the HJT module-controlled water flow began first and maintained a larger flow compared to TOPCon. As the light intensity decreased, the TOPCon-controlled water flow gradually diminished until it stopped, whereas the HJT module’s flow rate decreased only slightly, indicating its excellent low-light performance. This allows for extended power generation during dawn, dusk, cloudy, or smoggy conditions, improving overall efficiency.

Innovation-Driven Applications

At the Offshore Photovoltaic Industry Development Forum, held concurrently with the exhibition, Dr. Liu Songmin, Executive Vice President of the New Energy Research Institute of Grand Sunergy, delivered a keynote speech titled HJT Module Offshore Applications and 0BB Technology Progress. He also provided an in-depth analysis of the innovative applications of Grand Suenrgy’s Chasing HJT Seapower Solar Modules and 0BB technology, citing the 400MW offshore photovoltaic project in Zhaoyuan, Yantai.

He highlighted various challenges faced by offshore photovoltaics, such as high humidity, UV exposure, and corrosion from bird droppings and microorganisms, all of which test the durability and performance of photovoltaic modules.

Grand Suenrgy’s Chasing HJT Seapower Solar Modules utilize a polyurethane composite frame that offers excellent mechanical strength, weather resistance, and corrosion resistance. The module glass is protected by a dual-layer dense SiO2 coating, which effectively prevents erosion from seawater and salt fog, while the edge sealing process minimizes moisture ingress. These features make it highly suitable for high-temperature, high-humidity environments.

In terms of connectivity, the junction boxes and connectors of the Chasing HJT Seapower Solar Modules are designed with multiple sealing layers to prevent water and moisture intrusion. The solution has been successfully applied in the 400MW offshore photovoltaic project in Zhaoyuan, Yantai, demonstrating exceptional performance and reliability.

Dr. Liu also discussed the positive impact of 0BB technology, noting that it leads to increased power output and reduced silver consumption. For example, the power of the HJT-0BB module is increased by 5-10W compared to HJT-SMBB modules, while the silver consumption is reduced by 6mg/W.

Grand Sunergy has also introduced the Eutropic Series Super All-Black HJT Products, redefining the aesthetics of photovoltaic modules by incorporating a uniform black appearance.

Although challenges remain in offshore photovoltaic development, significant progress has been made, with China making a historic breakthrough in large-scale offshore photovoltaic installations. As a leader in N-type HJT technology, Grand Sunergy has demonstrated its strong innovative capabilities and forward-looking strategic vision in the field of offshore photovoltaics.