Recently, Grand Sunergy’s subsidiary, Anhui Grand Sunergy Technology Co., Ltd. (hereinafter referred to as ‘Grand Sunergy’), successfully won the bid for the photovoltaic module procurement project of the China Energy Construction Group Northwest Survey and Design Research Institute Co., Ltd.’s ‘CGN Yantai Zhaoyuan 400MW Offshore Photovoltaic Project (HG30)’. As the nation’s first fully-procedural and substantially-commenced nearshore pile-fixed offshore photovoltaic project, and also currently the largest single HJT offshore photovoltaic project in China, this project marks the official entry of China’s offshore photovoltaic power stations into the phase of large-scale development, signifying a groundbreaking milestone!

The CGN Yantai Zhaoyuan 400MW offshore photovoltaic project is located in the Laizhou Bay area in the northern part of Yantai’s subordinate county-level city, Zhaoyuan City. It covers a total planned area of approximately 6.44 square kilometers, consisting of 121 photovoltaic sub-arrays. The project’s AC-side rated capacity is 400MW, with a designed DC-side installation capacity of 539.3274MW. It exclusively employs Grand Sunergy’s 710W Offshore Photovoltaics series 210-132 double-sided, double-glass high-efficiency HJT modules. Among the first batch of ten offshore photovoltaic project sites competitively allocated in Shandong Province, it stands out as having the deepest water depth, the greatest construction difficulty, and the most complicated development conditions.

After completion, it is expected to generate an average annual electricity output of 690 million kilowatt-hours over a 25-year operating period, which can meet the annual electricity needs of approximately 400,000 households. This is equivalent to reducing coal consumption by about 207,000 tons per year and reducing carbon dioxide emissions by about 532,000 tons per year, providing a continuous source of green power for the economic and social development of Shandong Province.

Due to the harsh marine environment characterized by high humidity, high salt spray, high corrosion, high ultraviolet radiation, lightning surges, low-temperature ice and snow, biological fouling, and thermal shading challenges, offshore photovoltaic projects differ significantly from onshore photovoltaic projects in terms of early-stage planning, equipment selection, and product verification. They pose higher reliability requirements for component equipment selection for photovoltaic power plants, particularly in terms of resistance to water vapor intrusion, resistance to salt spray corrosion, excellent resistance to potential-induced degradation (PID), and mechanical strength. Any reliability failure in any section may directly affect the efficient and stable power generation throughout the entire lifecycle of the power station.

To fully address the complex and ever-changing marine application environment, Grand Sunergy has conducted targeted technical development and application scenario matching for modules in terms of encapsulation, glass coating, waterproofing, corrosion resistance, and UV resistance. As a result, it has developed double-glass, double-sided Heterojunction (HJT) modules with complete intellectual property rights, tailored for the unique marine environment.

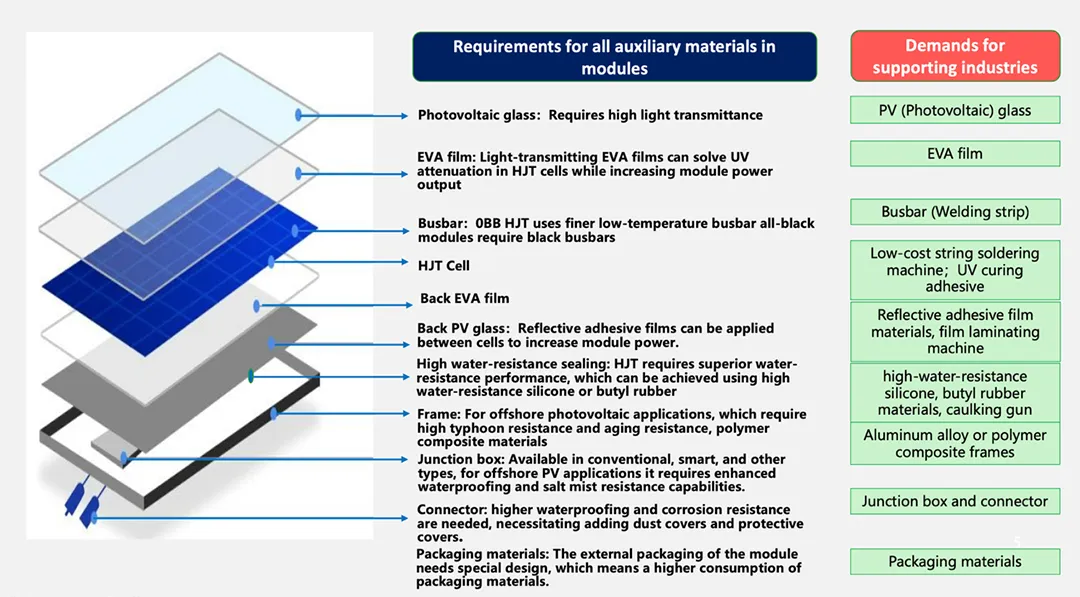

The 710W 210-132 model high-efficiency HJT modules provided by Grand Sunergy adopt 210mm large-size HJT cells, double-layer coated glass, UV-resistant encapsulation film, high-resistance water-sealing butyl rubber edge sealing, waterproof/salt spray-resistant junction box, and dust-proof plug/protective cover connectors. These utilize new processes and materials, significantly enhancing the module’s resistance to salt spray, corrosion, UV radiation, water vapor, and wind load. This upgrade in weather resistance further strengthens its reliability.

In Grand Sunergy’s offshore solar module solution, the Offshore Photovoltaics HJT series modules are equipped with an additional glass coating layer, enhancing the glass’s weather resistance and improving water resistance. This results in significantly enhanced acid, alkali, and salt spray resistance. In the module encapsulation process, the use of light-conversion films converts short-wavelength ultraviolet light into longer-wavelength blue light, increasing the module’s light utilization rate and eliminating power attenuation caused by strong UV light. Additionally, the edge sealing process employs a butyl rubber edge sealing technology, reducing water permeability by 99.9% compared to industry standards. This effectively prevents water vapor from infiltrating the module interior through the double-layer glass, making it highly suitable for hot and humid coastal environments.

It is worth mentioning that the Zhaoyuan 400MW project has been recognized by China General Nuclear (CGN) as a demonstration project for technological innovation, providing practical and applicable development and construction solutions for other similar offshore solar projects nationwide. This demonstrates its significant replicability and promotability.

The Yantai Zhaoyuan 400MW offshore solar project has strong demonstrative significance and driving effect in the industry, marking an important step forward for China’s offshore solar sector. The bidding for this offshore solar project was exclusively for HJT modules, indicating that the distinctive advantages of HJT technology have been fully recognized and appreciated by central state-owned enterprises and organizations for offshore applications.

Zhao Zhiyuan, Vice General Manager of Grandsunergy, stated: “Grandsunergy attaches great importance to the construction of offshore solar projects by China General Nuclear New Energy. We will spare no effort to allocate production capacity, technical teams, and research and development resources, and fully cooperate with the smooth progress of offshore solar projects. In the future, Grandsunergy will continue to focus on the construction of offshore solar projects, providing continuous supply of green and clean electricity, injecting new vitality and impetus into the construction of our beautiful China!”