From November 21-23, 2024, the 20th China SoG Silicon and PV Power Generation Conference (20th CSPV) was grandly held in Shenzhen. Dr. Zhang Zhongwei, Chief Scientist and Director of the New Energy Research Institute at Grand Sunergy, delivered a keynote speech titled Progress in Reducing Costs and Improving Efficiency in Heterojunction Mass Production.

Continuous Efficiency and Cost Reduction

HJT Accelerates Cost-Performance Improvement

Looking back at every cycle of fluctuations in the photovoltaic industry, the core driver has always been technological iteration. Driven by the demand for cost reduction and efficiency improvement in the photovoltaic industry, Heterojunction (HJT) cells, with their high-power generation performance and high system value, have gradually become a key strategy to break the homogenous competition in the photovoltaic sector.

On one hand, HJT cells feature a perfect bifacial passivation structure with an open-circuit voltage higher than that of TOPCon, enabling higher photoelectric conversion efficiency. On the other hand, HJT offers a clear cost reduction path, with companies paying greater attention to the coordinated development of the upstream and downstream industries. HJT has successively established technological industrialization collaborative innovation platforms and the 740W+ HJT Club, both of which further promote the advancement of HJT technology.

Based on advanced technologies such as 0BB, silver-coated copper, PIB, light conversion films, and fine metallization, in Q4 2024, Grand Sunergy’s Chasing Series G12-132 module achieved an average production power of 725W. The highest power achieved for a single module was 751.24W, with a maximum efficiency of 24.18%. Through continuous optimization of structure, process, materials, and equipment, it is expected that by 2025, Grand Sunergy’s Chasing Series G12-132 module will reach a mass-produced output power of 730-740W.

As the various photovoltaic cell technologies continue to develop, HJT is steadily improving cell efficiency, yield, and other product performance, while also continuously expanding its market share by reducing costs and improving efficiency. Dr. Zhang Zhongwei believes that the main cost reduction for HJT lies in ultra-thin silicon wafers, silver paste, 0BB, steel plate printing, target materials, and equipment. Using HJT-specific silicon wafers, low-silver paste, low-indium targets, and cost-reducing equipment, the overall cost of HJT is expected to decrease by more than 0.10 yuan/W. With further technological improvements and active cost reduction across the industrial chain, by 2025, the cost-performance ratio of HJT is expected to surpass that of TOPCon.

Leading System Value

Unlocking the Excellent Potential of Photovoltaic Technology

In addition to high conversion efficiency, high power, high bifaciality, high reliability, low temperature coefficient, low degradation, and a low carbon footprint, HJT modules also demonstrate superior weak light performance. In cloudy and rainy conditions, HJT modules outperform TOPCon modules, contributing about 0.5% to 1.0% more power per watt annually. When designing photovoltaic power stations, it is necessary to select inverters optimized for start-stop voltage to fully leverage the weak light response advantages of HJT modules.

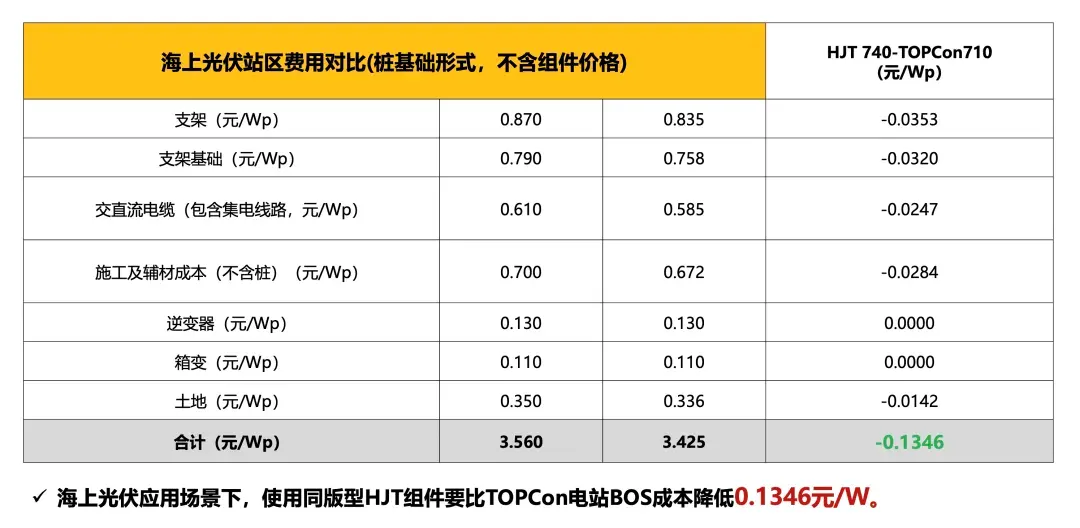

According to calculations, in offshore photovoltaic applications, Grand Sunergy’s 740W HJT-G12-132 Seapower modules can reduce the system BOS (Balance of System) cost by about 0.13 yuan/W compared to the same type of TOPCon modules. In desert photovoltaic applications, BOS costs can be reduced by about 0.04 yuan/W, and in commercial and industrial rooftop applications, BOS costs can be reduced by about 0.02 yuan/W.

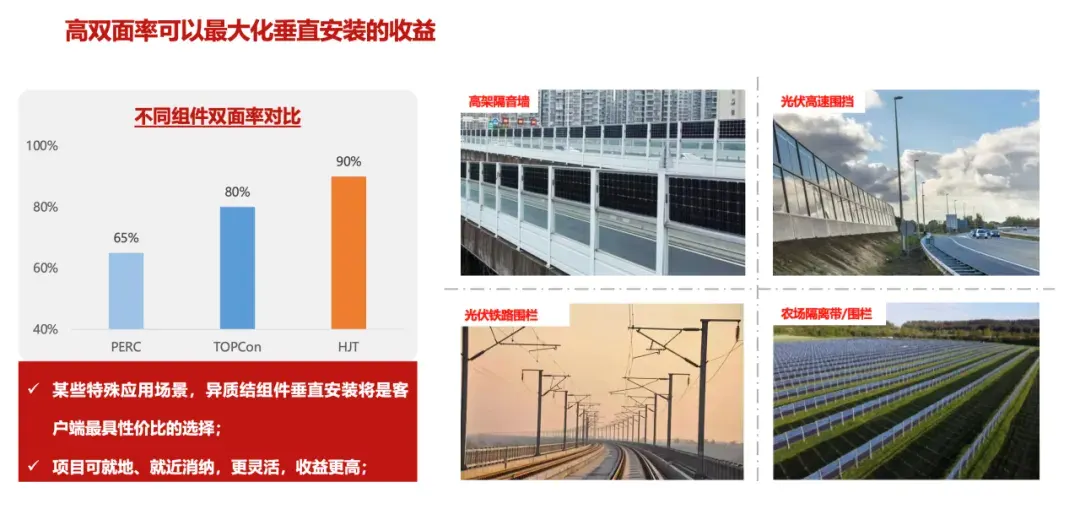

In vertical installation scenarios, due to the high bifaciality of HJT modules (up to 90%), they can achieve double-peak generation in the morning and afternoon. Vertical installations of HJT modules can generate about 20% more electricity than TOPCon modules. This makes them particularly suitable for marketized peak and valley electricity pricing models after the electricity price reforms. Therefore, in vertical installation scenarios such as high noise barriers, photovoltaic highway fences, photovoltaic railway fences, and farm isolation fences, projects can achieve higher local consumption and greater revenue, gradually becoming the most cost-effective choice for clients.

Moreover, to address the challenges of offshore (high EPC cost, salt mist corrosion, high humidity and heat, high load, high UV) and desert (high temperature differences, wind and sand erosion, high wind pressure loads, high UV) application scenarios, Grand Sunergy has developed special HJT modules with high power and low degradation. These modules have passed a series of stringent tests, including wind tunnel testing, three times PID testing, three times DH testing, and enhanced dynamic load testing. The company has accumulated extensive practical experience in “Photovoltaics+” application scenarios.

Cost reduction and efficiency improvement are the primary principles of the photovoltaic industry. Leveraging its deep technical expertise and mass production potential in HJT, Grand Sunergy continues to analyze the key pathways for reducing costs and improving efficiency in the mass production process of HJT. By focusing on improving battery conversion efficiency and reducing the cost of photovoltaic electricity, Grand Sunergy provides valuable insights for the healthy and sustainable development of the HJT technology route.